Project: Eco-Packaging Consultation

Background

MBA in Sustainable Business

As part of my Sustainable Packaging course during my MBA in Sustainable Business, our group project involved providing consultation to Tiny Green Farm, a microgreen company seeking a sustainable alternative to replace their current plastic clamshell packaging for storing microgreens.

Objective

Practical solutions to replace plastic clamshells

Our primary goal in this project is to identify a sustainable packaging solution that effectively replaces the existing plastic clamshell. The new packaging must meet specific criteria, such as being stackable, capable of preserving freshness, transparent, sufficiently sturdy for microgreen storage, and economically viable.

Sustainability Considerations

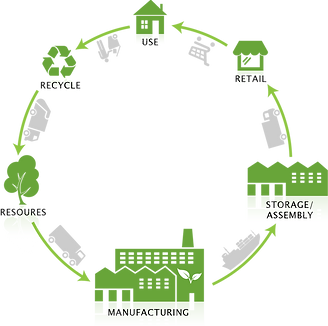

We embarked on a comprehensive sustainability analysis that considered the entire lifecycle of the packaging, examining its sourcing, materials used, manufacturing location, transportation method to the company, and its eventual decomposition process. Ideally, we sought locally sourced materials, biodegradable in nature, and transported using low greenhouse gas emission methods. However, practical implementation proved challenging. While options like polylactic acid (PLA) clamshells were compostable, the company's location lacked a public composting facility. Despite this setback, our search for a viable and sustainable alternative persisted.

Explore available options

Paper-based packaging

After weighing various factors, we gravitated towards paper-based solutions, particularly cardboard box, as the most promising option. Paper stands out for its biodegradability, and sourcing it locally proved more sustainable than importing alternatives. However, one challenge surfaced with paper-based packaging—issues concerning transparency and maintaining freshness. Many paper options lack transparency and struggle to preserve the product's freshness effectively.

Cellophane bags

To address the transparency and freshness concerns, we explored cellophane as a potential solution. While biodegradable, it also fell short in meeting all our requirements. Though it offered transparency and freshness retention, its lack of sturdiness posed a challenge in safeguarding delicate microgreens.

A Hybrid Packaging Solution

Harnessing the Strengths of both

Given the limitations in finding a single material meeting all criteria, we devised a hybrid approach. Combining cellophane's transparency and freshness retention with a paper clamshell's protective qualities, we proposed using a cellophane bag enclosed within a vented cardboard box. This innovative blend aimed to leverage the strengths of each material for an optimal packaging solution.

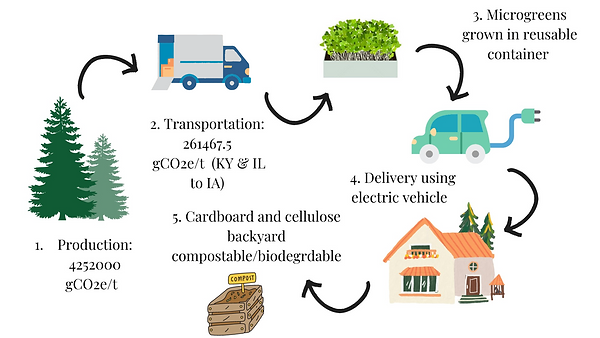

Summary

To conclude, after determining the suitable packaging size and conducting a life cycle assessment along with cost analysis, we identified the most feasible options. Both the cardboard box and cellophane bags are locally produced in the US, estimated to emit 4.5 tCO2e per ton. Comparatively, the current clamshell is manufactured and shipped from China, resulting in estimated emissions of 12 tCO2e per ton. This new packaging solution can potentially offset 7.5 tCO2e per ton of material, representing a reduction of over 60% in emissions. Despite a slight increase in cost (only 14%), the environmental benefits and reduced carbon footprint make it a compelling choice.